Compressed air energy storage (CAES) plant

Introduction to CAES

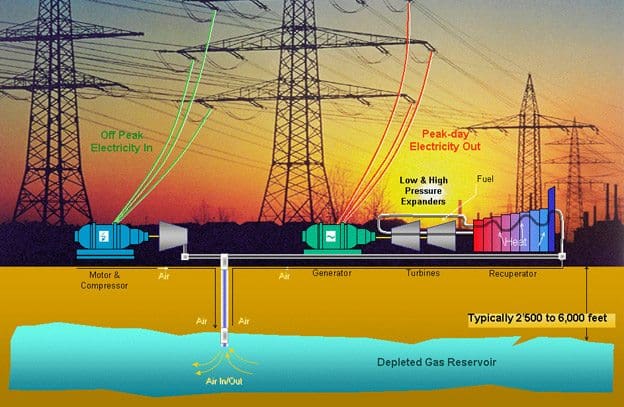

As the name implies, the compressed air energy storage (CAES) plant uses electricity to compress air which is stored in underground reservoirs. When electricity is needed, this compressed air is withdrawn, heated with gas or oil, and run through an expansion turbine to drive a generator. The compressed air can be stored in several types of underground structures, including caverns in salt or rock formations, aquifers, and depleted natural gas fields.

Typically the compressed air in a CAES plant uses about one third of the premium fuel needed to produce the same amount of electricity as in a conventional plant.

A 290-MW CAES plant has been in operation in Germany since the early 1980s with 90% availability and 99% starting reliability.

In the U.S., the Alabama Electric Cooperative runs a CAES plant that stores compressed air in a 19-million cubic foot cavern mined from a salt dome. This 110-MW plant has a storage capacity of 26 h.

The 290 MW Huntorf CAES station

The fixed-price turnkey cost for this first-of-a-kind plant is about $400/kW in constant 1988 dollars. The turbomachinery of the CAES plant is like a combustion turbine, but the compressor and the expander operate independently. In a combustion turbine, the air that is used to drive the turbine is compressed just prior to combustion and expansion and, as a result, the compressor and the expander must operate at the same time and must have the same air mass flow rate.

In the case of a CAES plant, the compressor and the expander can be sized independently to provide the utility-selected “optimal” MW charge and discharge rate which determines the ratio of hours of compression required for each hour of turbine-generator operation. The MW ratings and time ratio are influenced by the utility’s load curve, and the price of off-peak power.

For example, the CAES plant in Germany requires 4 h of compression per hour of generation. On the other hand, the Alabama plant requires 1.7 h of compression for each hour of generation.

At 110-MW net output, the power ratio is 0.818 kW output for each kilowatt input. The heat rate (LHV) is 4122 BTU/kWh with natural gas fuel and 4089 BTU/kWh with fuel oil.

Due to the storage option, a partial-load operation of the CAES plant is also very flexible.

For example, the heat rate of the expander increases only by 5%, and the airflow decreases nearly linearly when the plant output is turned down to 45% of full load. However, CAES plants have not reached commercial viability beyond some prototypes.

Resource: Saifur Rahman – Advanced Energy Technologies

Great post. Thanks for sharing!”

ReplyDeletePolyethylene Pipe Insulation

Insulated Underground Pipe