Where all this noise is coming from?

Yes, we all know that transformers are never silent. This is actually quite impossible, but in an environmentally aware, highly regulated world, the issue is not the level of noise, but its nature – and it’s very important.

Transformers emit a low-frequency, tonal noise that people living in their vicinity experience as an irritating “hum” and can hear even against a noisy background.

The power industry have a range of solutions to abate humming, which originates in the transformer’s core and, when it is loaded, in the coil windings. Core noise is generated by themagnetostriction (changes in shape) of the core’s laminations, when a magnetic field passes through them. It is also known as no-load noise, as it is dependent of the load passing through the transformer.

An effective and important noise source is the core of the transformer. The noise of the core depends on the magnetic property of the core material (sheet steel) and flux density. The sound frequency is low (twice the rated frequency). The magnetic forces formed in the core cause vibration and noise. The load noise occurs only on the loaded transforrmers and is added to the no-load (core noise). This noise is caused by the electromagnetic forces due to leakage fields.

The source of the noise are tank walls, magnetic screenings and vibrations of the windings.

The noises caused by the core and windings are mainly in the 100-600 Hz frequency band. The frequency range of the noise (aerodynamic/air and motor/bearing noise) caused by cooling fans is generally wide. The factors effecting the total fan noise are; speed, blade structure, number of fans and arrangements of the radiators.

The pump noise is not effective when the fans are working and it’s frequency is low.

Magnetostriction takes place at twice the frequency of the supply load: for a 50 Hz supply frequency, a lamination vibrates at 100 c/s. What’s more, the higher the density of the magnetic flux, the higher the frequency of the even-number harmonics.

When core or tank resonance frequencies coincide with the exciting frequency, the noise level further increases.

Hum also arises through the vibration caused when the load current passes through the windings, interacting with the leakage flux it generates. This load noise level is determined by the magnitude of the load current. It has always existed, but is becoming proportionally more significant since there are efficient means of reducing the core noise source.

In some situations, the load noise is the dominant noise and is raising increasing concern among new transformer applications.

Note that the broadband noise generated by cooling fans contributes to overall noise levels. But as cooling fans are widely used in the industry, solutions are not specific to transmission and distribution and so are not discussed here.

Vibroacoustic energy sources in the power transformers

Power transformer noise is mainly a low frequency narrow band noise, and the noise spectrum includes the tonal components of the frequency being the multiple of the power line frequency. The power transformers have many sources of vibroacoustic energy.

The most important sources include:

- The transformer core vibration as an effect of the magnetostriction phenomena

- The transformer winding vibration as an effect of the electrodynamic forces

- The devices of the transformer cooling system, as fans, oil pumps.

Matters of design

Improvements in standard transformer design and materials are cutting the decibel count.

High-permeability (Hi-B) steel, for example, restricts magnetostriction through a surface coating with higher degrees of grain orientation.

Another increasingly popular method is high-precision stacking of the core’s laminations in step-lap patterns, reducing the formation of air gaps in the core joints. Focus on the linkages between the laminations to stop them striking each other includes gluing their edges together, standardizing clamp pressure and removing through-bolts.

In addition, robust, flexible mounts at all points of contact between core and tank inhibit the structure- or oil-borne transmission of resonance from one to the other.

Sound ways of seeing

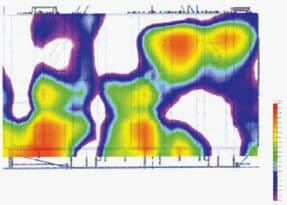

Areva T&D’s R&D department employs acoustic imaging, acoustic holography and laser vibrometry to locate noise and vibrations. Acoustic maps noise rapidly and comprehensively by differentiating sound levels to determine where it radiates from.

Areva T&D and AB Engineering used 110-microphone arrays 2 m from the tank to measure noise in the 100 Hz to 500 Hz frequency bands.

For each band, an identically scaled map showed red hot spots on noise-free blue backgrounds, making it easy to pinpoint noise sources. Acoustic holography which analyzes near-field noise, was recently used to map transformer noise, arranging a 23-microphone antenna to scan a grid of 20 x 20 cm squares. Algorithm-based software computed the pressure field and sourced the acoustic radiation, displayed as spatially distributed 2-D maps for different frequencies up to 850 Hz.

Laser vibrometry is a no-contact technique for inaccessible or dangerous targets. It uses the Doppler effect, measuring the frequency modulation in the laser beam that rebounds from the vibrating target. Laser vibrometers can automatically scan large numbers of consecutive points, delivering vibration measurements with high spatial resolution.

When a transformer is loaded, vibration energy from the coil and any flux control devices is transmitted to the tank and then to the air and local environment. It is therefore important to design the tank so that it does not resonate at frequencies close to the exciting frequency. Measures like resonance absorbers can gain 3 dB.

On-site solutions

A common on-site method of containing noise radiation is tank-supported wall panels. They generally cover only the sides of the tank, bringing gains of between 4 dB and 10 dBdepending on the wall area they cover. They may affect cooling, so acoustic barriers are often used, mounted close to the transformer on one or more sides, or enclosing it.

The simplest solution is a high acoustic screen, which must extend past each end of the transformer by at least as much as it exceeds the height of the transformer. But even single barriers can lower noise levels by 10 – 15 dB, depending on the position of the observer.

|

| Acoustic holography is used to map transformer noise |

Complete top-bottom-and-side enclosure, of course, produces the most radical results, up to 25 dB of abatement, or even 40 dB if the enclosure is a massive structure made of concrete or steel and fully vibration-insulated. Care should always be taken that the space between tank wall and the barrier is not an even multiple of half of the wave length of the power frequency, e.g., 1,7 m, 3,4 m, etc. for 50 Hz transformers.

The result is standing waves that will cause echoes and amplify sound levels. Attenuation depends on how and how many of these methods are used. Combining Hi-B step-lapped core lamination with core vibration isolators can gain 6 dB. Add tank-mounted wall panels and that is 10 dB.

For greater improvement, a total contact-free enclosure is the answer.

Of course, designers can build low noise into transformers by lowering the core’s induction level, or flux density. But the trade-off is a larger core, larger windings and higher costs.

Need for Research and Development

Reasearch and development is addressing the need for reduced sound levels.

Some abatement techniques are well known, but others can be very innovative, such as resonance absorbers or resilient internal lining absorbers. Most of the selected solutions require a good knowledge of noise field and vibration mapping. New techniques are available to identify this information and to better characterize noise sources.

Benefits can be a reduction of measurement time, facilitated interpretation of measurements, access to other information (as in source localization), and more.

No comments:

Post a Comment