The word “geothermal”

comes from the Greek words geo (earth) and thermal (heat). It means the

heat of earth. The energy potential beneath our feet, in the form of

geothermal energy, is vast.

This tremendous resource amounts to

50,000 times the energy of all oil and gas resources in the world.

Geothermal energy has attracted worldwide attention as an alternate

source of energy for the last few decades. Presently this

non-conventional energy constitutes about 1% of the total global

electricity output but the scenario is changing very fast due to its

eco-friendly pollution free and renewable nature. About onethird of the

total available energy is spent on space heating, bathing, fish and

green house farming and industrial uses.

The USA, Iceland, China and New Zealand make maximum use of geothermal energy for electricity generation or as heat energy.

Together,

geothermal power plants and direct-use technologies are a winning

combination for meeting our country’s energy needs while protecting the

environment. Whether geothermal energy is used for producing electricity

or providing heat, it’s a clean alternative for the nation. And

geothermal resources are domestic resources. Keeping the wealth at home

translates to more jobs and our national economic and employment picture

improve.

Geothermal Energy Explained

|

| The heat geothermal energy |

The Earth’s crust is a bountiful source of energy.

Nearly everyone is familiar with the Earth’s fossil fuels oil, gas, and

coal but fossil fuels are only part of the story. Heat, also called

thermal energy, is by far the more abundant resource. The Earth’s core,

4000 miles (6437 kilometers) below the surface, can reach temperatures

of more than 9000°F (4982°C).

The heat geothermal energy

constantly flows outward from the core, heating the surrounding area.

Nearby rock melts at high temperatures and pressure, transforming into

magma.

Magma can some times well up to the surface as lava, but

most of the time it remains below the Earth’s crust heating nearby rock.

Water seeps into the Earth and collects in fractured or porous hot

rock, forming reservoirs of steam and hot water. If those reservoirs are

tapped for their fluids, they can provide heat for many uses, including

electricity production.

Geothermal Drilling

Before

the Earth’s heat can be used for purposes such as generating

electricity or heating buildings, conduits between the geothermal

reservoir of hot water or steam and the Earth’s surface must be

provided. This is done by drilling production and injection wells, which

are often thousands of feet deep, into the reservoir. Drilling of

exploratory wells also helps collect data to define the size and

productivity of the geothermal reservoir. Construction of wells is

clearly essential, but it is also expensive, accounting for 15 to 30

percent of the total cost of a geothermal power project.

To drill

almost any well, a drill bit is mounted on the end of a long metal pipe

called the drill string, which is rotated from the surface by machinery

called a drill rig. New 30-foot lengths of pipe are added to the top of

the drill string as the bore hole gets deeper. To cool and lubricate the

drill bit and to carry away the chips of rock cut by it, a viscous

fluid called drilling mud is pumped down the drill string.

The mud

passes through holes in the drill bit and then flows back up the hole

in the space between the bore hole wall and the drill string.

Drill Bits

Drilling

costs are greatly affected by how quickly the drill bit can penetrate

the hard, abrasive, fractured rocks of a geothermal location, and by how

long it can last before the drill string needs to be taken out of the

hole to replace the bit. If both penetration rate and bit life were

doubled, drilling costs would drop an average of 15 percent.

Two kinds of bits are used:

- Roller-cone bits

- Polycrystalline diamond compact (PDC) bits

For

virtually all drilling in either geothermal or oil and gas wells

roller-cone bits and polycrystalline diamond compact (PDC) bits. Roller

cone bits have toothed cones that roll on the bottom of the hole as the

bit rotates, each tooth crushing the small area of rock beneath it.

|

Polycrystalline diamond compact

|

The

PDC bit uses thin layers of synthetic diamond bonded to tungsten

carbide-cobalt studs or blades. The diamond layer gives the cutter

extreme resistance to abrasive wear in the shearing action of cutting.

PDC bits are especially well suited to drilling through hot rock because

they have no moving parts, so high-temperature seals, bearings, and

lubricants are not an issue. They have gained this tremendous market

acceptance because they have consistently drilled faster and lasted

longer than roller cone bits. For geothermal drilling, however, PDC bits

do not work reliably well in rock that is more than moderately hard.

These

efforts will lead to enhance performance, extending full application of

PDC bits, with its attendant cost savings, to the hot, hard rocks of

geothermal reservoirs.

Bore hole Measurements

Measurements

in the borehole are used both to evaluate the reservoir once the well

is drilled and to provide data during drilling that will make the

process faster, cheaper, and safer. To function effectively for

geothermal drilling, this instrumentation must be adapted for slim hole

drilling and high-temperature conditions. Sandia has developed tools

that meet these temperature and size requirements, including a promising

new self contained, battery-powered, memory-storage system. Several of

these tools have been used extensively in the field and are available

for application or have been commercialized; others are in the late

stages of testing.

Baker Hughes has signed a licensing agreement

with DOE for use of down hole instrumentation, and Board Long year, a

supplier of drilling equipment for geothermal and mineral exploration,

recently commercialized core tube data logging equipment.

Electricity Production

Electricity

production using geothermal energy is based on conventional steam

turbine and generator equipment, where expanding steam powers the

turbine/ generator to produce electricity. Geothermal energy is tapped

by drilling wells into the reservoirs and piping the hot water or steam

into a power plant for electricity production.

Types or geothermal power plants:

- Dry steam

- Flash steam

- Binary cycle

Dry steam power plants

|

Dry steam power plants

|

The

steam is piped directly from wells to the power plant, where it is

directed into a turbine. The steam turns the turbine, which activates a

generator. The steam is then condensed and injected back into the

reservoir via a well.

Dry steam is the oldest type of plant first used in Italy in 1904 but it is still very effective.

The Geysers in northern California, the world’s largest single source of geothermal power, uses dry steam.

.

Flash steam power plants

|

Flash Steam Power Plants

|

Flash steam power plants

tap into reservoirs of water with temperatures greater than 360°F

(182°C). This very hot water flows up through wells in the ground under

its own pressure. As it flows, the fluid pressure decreases and some of

the hot water boils or “flashes” into steam.

The steam is then

separated from the water once at the surface and is then used to power a

turbine/generator unit. The remaining water and condensed steam are

injected through a well and back into the reservoir.

Binary cycle power plant

|

| Binary cycle power plant |

Binary

cycle power plants operate on water at lower temperatures of about 225°

to 360°F (107° to 182°C). These plants use the heat from the geothermal

water to boil a working fluid, usually an organic compound with a low

boiling point. The working fluid is vaporized in a heat exchanger and

used to turn a turbine.

The water is then injected back into the

ground to be reheated. The water and the working fluid are confined to

separate geothermal temperatures required for direct use 70° to 302°F

(21° to 150°C) are lower than those for electric power generation.

Hot

water from geothermal resources can be used directly to provide heat

for industrial processes, crop drying, or heating buildings. This

is called direct use. The consumer of direct-use geothermal energy can

count on savings of as much as 80 percent from traditional fuel costs,

depending on the application and the industry.

Direct-use systems

do require a larger capital investment compared to traditional systems,

but have lower operating costs and no need for ongoing fuel purchases.

Geothermal Heat Pumps

|

Geothermal Heat Pumps

|

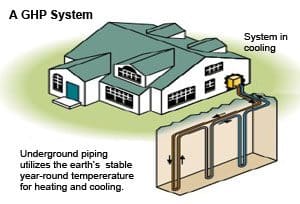

Geothermal

heat pumps, also known as GHPs, enable the ground to serve as an energy

storage device.GHPs are similar to conventional air conditioners or

refrigerators.GHPs discharge heat to the ground during the cooling

season and extract useful heat from the ground during the heating

season.

GHPs marketed today also provide hot water. There are over

500,000 GHPs in service today in the United States, including about 600

systems at schools and colleges.

Heating

The direct use of the geothermal resource, however, evolved into a modern system that today provides space and domestic water heating

throughout the city of Boise to many homes, businesses, and government

buildings. The hot water from a geothermal well can replace the

traditional heat source often natural gas of a boiler, furnace, and hot

water heater.

Geothermal water can also heat a working fluid that

melts snow as it flows through piping installed underneath pavement.

Generally, an individual home or building only needs one geothermal well

for a heating system. In larger applications, like in Boise, a district

heating system can be used to supply heat from a central location of

one or more wells through a network of pipes to entire blocks of

buildings. percent compared to the cost of natural gas heating.

The savings are much higher when compared to electric, propane, or fuel oil heating systems.

|

Geothermal District Heating System

|

Agricultural

This

number continues to rise as word spreads about the benefits of direct

use in agriculture, such as lower operating costs and increased growth

rates. These can be significant competitive advantages. Many crops like

cucumbers, tomatoes, flowers, houseplants, tree seedlings, and cacti

flourish in geothermally heated greenhouses.

Several fish farms

and other aquaculture operations have found success using geothermal

water as a habitat for their livestock, making it the fastest growing

direct-use application in the country.

Industrial

Geothermal

direct use continues to show great commercial potential and competitive

advantages for a variety of industries. Industrial applications include

food dehydration, gold mining, laundries, milk pasteurizing, mushroom

culture, and sewage digestion. Geothermal direct-use resources are

especially well suited to vegetable dehydration operations, such as in

the production of dried onions or garlic. The dry climates throughout

much of the West also assist in the process.

The dehydration

process begins with geothermal water flowing through a heat exchanger,

which warms the air to temperatures ranging from 100° to 220°F (38° to

104°C).

Clean Energy from the Earth for the 21st Century

DOE

funds research to reduce the cost of geothermal components, systems,

and operations. Geothermal facilities use the natural heat in the

earth’s interior to produce electricity or to satisfy other heat energy

needs. The Program’s R&D activities closely align with its mission

and goals.

With improved exploration methods, industry will locate

and characterize new geothermal fields more accurately, reducing the

high cost and risk of development. Better technology for drilling wells

will make it possible to access deeper resources and reduce costs,

thereby expanding the economic resource base.

Advances in energy

conversion will establish air-cooled binary technology as a means of

generating competitively priced electricity from more plentiful

lower-temperature resources. These activities all contribute directly to

reducing the cost of geothermal development and enabling the

installation of more geothermal facilities. Geothermal electric

generation projects are capital-intensive enterprises, with the major

expenses being incurred before the plant begins to produce revenue. The

high-cost components of a geothermal development project include:

drilling exploration, production, and injection wells; and plant

equipment and construction.

The primary risk in a geothermal

project is confirmation of a viable reservoir, which usually requires

extensive drilling and well testing.

To help reduce the risks and costs in geothermal development, the program’s research strategy involves:

- Improving technologies for exploration, detection of fractures and permeable zones, well sitting, and fluid injection

- Decreasing the cost of drilling and completing geothermal wells

- Reducing the capital, operation, and maintenance costs of geothermal power plants.

Conclusion

Reducing

drilling costs will substantially cut the costs of geothermal

development, thus helping the domestic geothermal industry to maintain

its world-leader status and to expand its markets. Today, society uses

only a small fraction of the geothermal energy resource base. The

ultimate promise of geothermal energy is that a much larger fraction of

the total resource base can be tapped.

New and improved drilling technologies can make this happen.

No comments:

Post a Comment