The acronym FACTS stands for “flexible AC transmission systems.”These

systems add some of the virtues of DC, i.e., phase independence and

fast controllability, to AC transmission by means of electronic

controllers. Such controllers can be shunt or series connected or both.

They represent variable reactances or AC voltage sources. They can

provide load flow control and, by virtue of their fast controllability,

damping of power swings or prevention of subsynchronous resonance (SSR).

Typical

ratings of FACTS controllers range from about thirty to several hundred

MVAr. Normally they are integrated in ac substations. Like HVDC converters, they require controls, cooling systems, harmonic filters, transformers, and related civil works.

Static VAR compensators (SVC) are the most common shunt-connected controllers. They are, in effect, variable reactances.

SVCs

have been used successfully for many years, either for load (flicker)

compen-sation of large industrial loads (arc furnaces, for example) or

for transmission compensation in utility systems.

Figure 1

shows a schematic one-line diagram of an SVC, with one

thyristor-controlled reactor, two thyristor switched capacitors, and one

harmonic filter.

|

| Figure 1 - Schematic one-line diagram of an SVC |

1 - Transformer

2 - Thyristor- controlled reactor (TCR)

3 - Fixed connected capacitor/filter bank

4 - Thyristor-switched capacitor bank (TSC)

2 - Thyristor- controlled reactor (TCR)

3 - Fixed connected capacitor/filter bank

4 - Thyristor-switched capacitor bank (TSC)

The

thyristor controller and switches provide fast control of the overall

SVC reactance between its capacitive and inductive design limits. Due to

the network impedance, this capability translates into dynamic bus

voltage control. As a consequence, the SVC can improve transmission

stability and increase power transmission limits across a given path.

Harmonic

filter and capacitor banks, reactors (normally air core), step-down

transformers, breakers and disconnect switches on the high-voltage side,

as well as heavy-duty buswork on the medium voltage side characterize

most SVC stations. A building or an e-house with medium voltage wall

bushings contains the power electronic (thyristor) controllers. The

related cooler is usually located nearby.

A new type of controlled shunt compensator, a static compensator called STATCOM, uses voltage-sourced converters with high-power gate-turn-off thyristors (GTO), or IGBT [17, 18].Figure 2

shows the related one-line diagram. STATCOM is the electronic

equivalent of the classical (rotating) synchro-nous condenser, and one

application of STATCOM is the replacement of old synchronous condensers.

|

Figure 2 - One-line diagram of a voltage sourced Static Compensator (STATCOM)

|

The

need for high control speed and low maintenance can support this

choice. Where the STATCOM’s lack of inertia is a problem, it can be

overcome by a sufficiently large dc capacitor. STATCOM requires fewer

harmonic filters and capacitors than an SVC, and no reactors at all.

This makes the footprint of a STATCOM station significantly more compact than that of the more conventional SVC.

Like

the classical fixed series capacitors (SC), thyristor-controlled series

capacitors (TCSC) [19, 20] are normally located on insulated platforms,

one per phase, at phase potential. Whereas the fixed SC compensates a

fixed portion of the line inductance, TCSC’s effective capacitance and

compensation level can be varied statically and dynamically. The

variability is accomplished by a thyristor-controlled reactor connected

in parallel with the main capacitor.

This circuit and the related main protection and switching components are shown in Figure 5.10.

The thyristors are located in weatherproof housings on the platforms.

Communication links exist between the platforms and ground. Liquid

cooling is provided through ground-to-platform pipes made of insulating

material.

Auxiliary platform power, where needed, is extracted

from the line current via current transformers (CTs). Like most

conventional SCs, TCSCs are typically integrated into existing

substations. Upgrading an existing SC to TCSC is generally possible.

|

Figure 3 - Schematic diagram of one phase of the Serra da Mesa (Brazil) Thyristor-controlled Series Capacitor (TCSC)

|

A

new development in series compensation is the thyristor-protected

series compensator (TPSC). The circuit is basically the same as for

TCSC, but without any controllable reactor and forced thyristor cooling.

The

thyristors of a TPSC are used only as a bypass switch to protect the

capacitors against overvoltage, thereby avoiding large MOV arrester

banks with relatively long cool-off intervals. While SVC and STATCOM

controllers are shunt devices, and TCSCs are series devices, the

so-called unified power flow controller (UPFC) is a combination of both

[21].

Figure 4 shows the basic

circuit. The UPFC uses a shunt-connected transformer and a transformer

with series-connected line windings, both interconnected to a dc

capacitor via related voltage-source-converter circuitry within the

control building.

|

Figure 4 - One-line diagram of a Unified Power Flow Controller (UPFC)

|

A

more recent FACTS station project involves similar shunt and series

elements as the UPFC, and this can be reconfigured to meet changing

system requirements. This configuration is called a convertible static

compensator (CSC).

The ease with which FACTS stations can be

reconfigured or even relocated is an important factor and can influence

the substation design. Changes in generation and load patterns can make

such flexibility desirable.

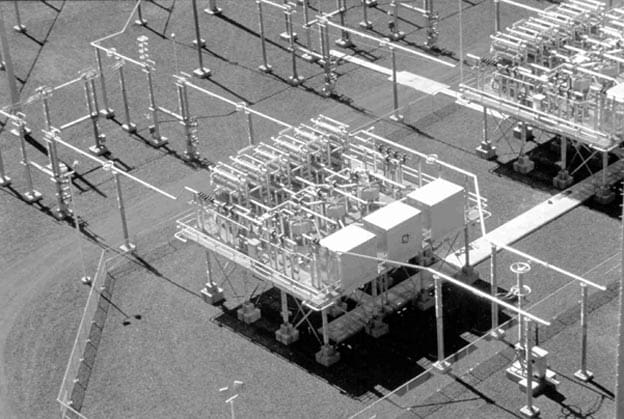

Figure 5

shows a 500-kV AC feeder (on the left side), the transformers (three

single-phase units plus one spare), the medium-voltage bus, and three

thyristor-switched capacitor (TSC) banks, as well as the building that

houses the thyristor switches and controls.

|

| Figure 5 - 500 kV, 400 MVAr SVC at Adelanto, California (by SIEMENS) |

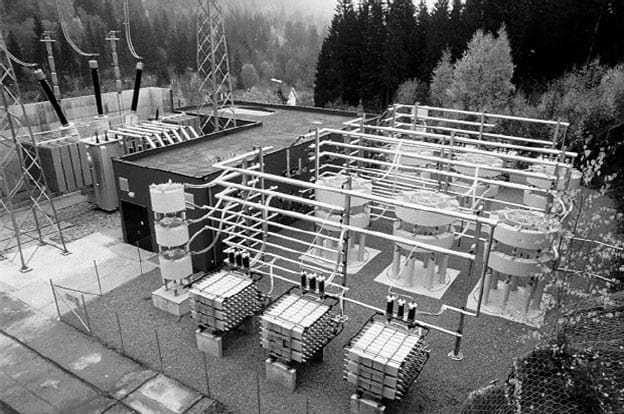

The SVC shown in Figure 6

is connected to the 420-kV Norwegian ac grid southwest of Oslo. It uses

thyristor controlled reactors (TCR) and TSCs, two each, which are

visible together with the 9.3-kV high-current buswork on the right side

of the building.

|

Figure 6 - 420 kV, ±160 MVAr SVC at Sylling, Norway (by ABB)

|

Figure 7

show photos of two 500-kV TCSC installations in the U.S.. The

platform-mounted valve housings are clearly visible. Slatt (U.S.) has

six equal TCSC modules per phase, with two valves combined in each of

the three housings per bank.

|

| Figure 7 - Aerial view of BPA’s Slatt, Oregon, 500kV TCSC (by GE) |